Getting the right thickness when applying paint and coatings is crucial for proper testing and quality control. ASTM D823-18 provides five standardized practices for creating uniform paint films on test panels, helping you achieve consistent and reliable results in your coating applications.

This standard, first established in 1945 and updated in 2022, falls under the oversight of the ASTM Committee D01 on Paint and Related Coatings. It gives you specific methods to prepare test panels that meet industry requirements for thickness uniformity.

You’ll find detailed guidelines for applying coatings to test panels, which is essential for accurate performance testing and quality assessment of paints and similar products. These practices ensure your test results are reliable and comparable across different testing scenarios.

Key Takeaways

- The standard outlines five distinct methods for applying uniform paint films to test panels

- Your test results become more reliable when following these standardized application practices

- Paint thickness uniformity directly affects the accuracy of performance testing and quality control

Scope of ASTM D823-18

ASTM D823-18 provides standard practices for creating uniform paint and coating films on test panels. These practices help you achieve consistent results when testing paint properties.

The standard covers three main methods for applying coatings:

- Method A: Hand-operated film applicators

- Method B: Mechanical film applicators

- Method C: Spray application equipment

You can use these practices to prepare test panels for evaluating paint quality, durability, and appearance. The methods work with paints, varnishes, lacquers, and related coating materials.

The standard falls under ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications. Subcommittee D01.23 on Physical Properties of Applied Paint Films manages these practices.

These practices help you create test specimens with uniform thickness. This uniformity is essential for accurate testing of coating performance and characteristics.

Referenced Documents

ASTM D823-18 lists several key standards and test methods that support proper film thickness measurement and panel preparation for paint and coating testing.

Standards Referenced

O test method for measuring dry film thickness references ASTM D1005, which uses micrometers for organic coatings.

You’ll need to follow ASTM D609 when preparing cold-rolled steel panels for testing paints, varnishes, and conversion coatings.

For wet film thickness measurements, use ASTM D1212 test methods specifically designed for organic coatings.

These standards work together to ensure consistent and accurate testing procedures. You must follow each referenced standard’s specific requirements to maintain proper testing conditions and get reliable results.

Bold text indicates critical standards:

- ASTM D609 – Steel panel preparation

- ASTM D1005 – Dry film measurement

- ASTM D1212 – Wet film measurement

Terminology

Key terms in ASTM D823 help paint manufacturers and technicians create uniform test films using standardized application methods and measurements.

Definitions of Terms Specific to This Standard

Paint film application techniques include drawdown, where you pull paint across a surface with a blade or bar to create an even coating thickness.

Film thickness refers to the measured depth of the dried coating on your test panel. You must maintain consistent thickness across the entire panel surface.

A test panel is your prepared substrate material, like metal or plastic, that you’ll apply the coating to for evaluation.

Uniform film means the coating has even distribution and consistent thickness, without areas that are thicker or thinner than specified. You need this uniformity to get accurate test results.

Automated spray application uses machine-controlled spray equipment to apply coatings with precise, repeatable settings for pressure, distance, and speed.

Significance and Use

ASTM D823 practices are essential when working with coatings meant for spray applications in factories or field settings. These methods help you achieve consistent results whether you’re coating objects indoors or outdoors.

The practices are particularly important when you need to evaluate metallic coatings for their appearance qualities. This includes testing properties like gloss and color consistency across surfaces.

When you apply coatings using these test methods, you may notice a slight orange-peel texture or spray wave pattern. This is normal and matches what you’d typically see in real-world applications.

These standardized application methods ensure your test results are reliable and repeatable. You can use them to compare different coating products or evaluate coating performance under various conditions.

O five distinct practices give you flexibility in choosing the most appropriate method for your specific coating type and testing needs. Each practice helps you create uniform film thickness, which is crucial for accurate testing and evaluation.

Apparatus

Proper equipment and tools are essential for producing uniform paint films and coatings on test panels. The specific requirements for panels, application tools, and testing equipment ensure consistent and reliable results.

Test Panel Specifications

Test panels must be flat, rigid, and clean to achieve uniform coating thickness. You should use panels made from steel, aluminum, glass, or other ASTM-approved materials.

The panels need precise dimensions with squared edges and no surface defects. Standard panel sizes range from 3×6 inches to 6×12 inches, depending on your testing requirements.

Surface preparation is critical. Clean panels thoroughly with solvents to remove oils, dust, and contaminants before coating application.

Film Application Tools

Five main application methods are used for creating uniform films:

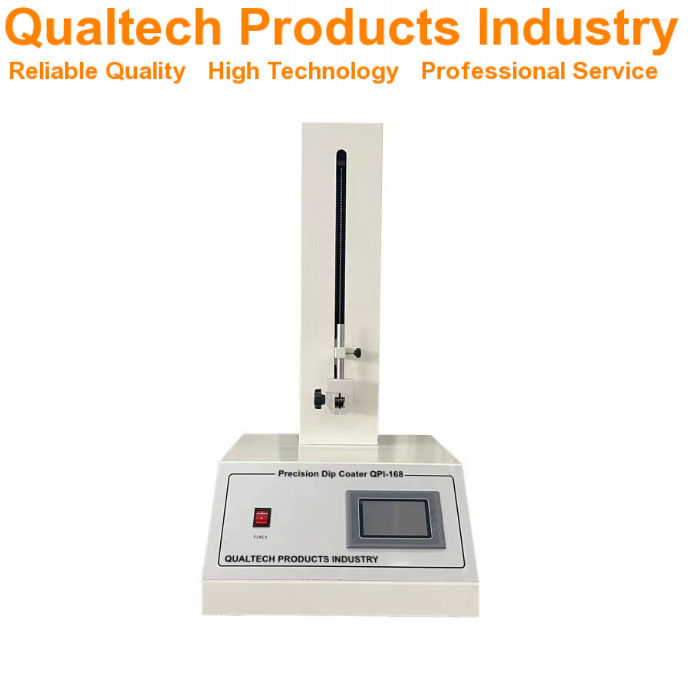

- Automated spray machines

- Motor-driven dip coaters

- Motor-driven blade applicators

- Hand-held spray guns

- Manual blade applicators

Each tool must be properly maintained and calibrated before use. Automated equipment provides better consistency than manual methods.

Keep spray nozzles clean and adjusted to the correct settings. Replace worn blades and applicators regularly.

Conditioning and Testing Equipment

Your testing area needs controlled temperature and humidity conditions. Use calibrated thermometers and hygrometers to monitor the environment.

Standard conditions require:

- Temperature: 23 ± 2°C

- Relative Humidity: 50 ± 5%

Film thickness gauges and measuring devices must be properly calibrated. Store panels horizontally in dust-free conditions while films cure.

Use appropriate drying racks that don’t disturb the wet film. Monitor cure times according to coating specifications.

Test Specimens

Proper test panel preparation and film application methods are essential for achieving accurate coating evaluation results. These practices help ensure consistent, reliable testing of paints and coatings.

Preparation of Test Panels

Test panels must be clean and free from contaminants before coating application. Select panels made from metal, glass, plastic, or wood based on your testing requirements.

Clean panels thoroughly with solvents appropriate for the substrate material. For metal panels, use mineral spirits or acetone to remove oils and residues.

Sand the surface if needed to achieve proper roughness and adhesion characteristics. Wipe panels with lint-free cloths to remove dust.

Panel preparation guidelines specify maintaining consistent temperature and humidity during preparation, typically 23°C ± 2°C and 50% ± 5% relative humidity.

Film Application

Five standardized practices exist for applying uniform coating films: automated spray machine, motor-driven dip coater, motor-driven blade, hand-held spray gun, and drawdown techniques.

Choose your application method based on the coating type and required film thickness. Automated methods provide better repeatability than manual techniques.

Maintain proper application conditions:

- Temperature: 23°C ± 2°C

- Relative humidity: 50% ± 5%

- Air flow: Minimal draft

- Surface position: Horizontal or vertical as specified

Allow films to cure under controlled conditions. Record application method, conditions, and cure time for each specimen.

Procedure

The paint application process requires careful control of conditions and techniques to achieve high-quality test results. Following standardized methods ensures consistent film thickness and proper coating performance.

Environmental Conditions

You must maintain specific temperature and humidity levels in your testing area. Keep the room temperature between 23°C ± 2°C (73.4°F ± 3.6°F).

The relative humidity should stay between 50% ± 5%. Check these conditions at least 24 hours before starting the application process.

Record environmental readings at the start and end of each coating session. This helps track any variations that might affect film formation.

Coating Uniformity

Apply the coating using automated spray equipment for the most consistent results. Set the spray gun mount to move at a steady speed across the test panel.

Maintain a constant distance between the spray nozzle and test panel surface. The typical range is 6-8 inches.

Check the coating thickness while it’s wet using a wet film thickness gauge. Make several measurements across the panel surface.

Look for any signs of:

- Orange peel texture

- Runs or sags

- Uneven coverage

- Edge buildup

Drying and Curing

Position coated panels horizontally during initial drying. This prevents runs and ensures even film formation.

Keep panels away from direct airflow or heat sources during the first stages of drying.

Follow the manufacturer’s recommended cure times and temperatures. Most coatings need:

- 24-48 hours at room temperature

- OR 30-60 minutes at elevated temperatures (specified by coating type)

Test the hardness and adhesion only after full cure. Early testing can damage the coating film.

Report

Proper reporting of test results from paint film thickness measurements ensures data accuracy and repeatability across different testing environments.

General Reporting Requirements

You must document all test conditions and methods used during the film thickness measurement process. Record the ambient temperature and relative humidity of the testing environment.

List all equipment used, including calibration dates and equipment identification numbers. Document any deviations from standard testing procedures.

Note the specific type and batch number of paint or coating tested. Include details about the test panel material, surface preparation methods, and application techniques used.

Test Results

Record film thickness measurements in micrometers or mils, taking multiple readings at specified points across the test panel surface. Include both individual measurements and calculated average values.

Note any defects, irregularities, or non-uniform areas observed in the coating film. Document visual observations of film quality, including surface texture and appearance.

Provide statistical analysis of measurement data when required, including standard deviation and variance. Include photographs or diagrams of measurement locations on test panels when needed for clarity.

Precision and Bias

ASTM D823-18 does not include specific precision and bias data for the described practices. This is because the method focuses on preparation techniques rather than measurement results.

The precision of your film thickness will depend heavily on your equipment calibration and skill level. You need to maintain proper calibration of all measuring devices and applicators.

Regular verification of your test panels and application methods helps ensure consistent results. You should check your procedures against the ASTM D823 standard practices to maintain quality.

Common factors affecting precision include:

- Environmental conditions

- Application technique

- Equipment maintenance

- Panel preparation quality

- Film applicator condition

Your coating thickness measurements must be made according to appropriate ASTM standards for the specific type of coating being tested. This ensures your results can be compared with other labs following the same procedures.

When you report results, note any deviations from standard practices that might affect the uniformity of the film thickness. Keep detailed records of application conditions and methods.

Keywords

Paint films, coatings, test panels, film thickness, application methods, paint thickness testing, film uniformity.

ASTM D823-18 falls under the scope of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications.

The specific subcommittee responsible for this standard is D01.23 which focuses on Physical Properties of Applied Paint Films.

These standard practices were first established in 1945 and the current version was approved in 2022.

Key terms you’ll encounter in this standard include:

- Film application

- Coating thickness

- Test panel preparation

- Uniform film production

- Paint application methods

- Quality control testing

- Surface preparation

Frequently Asked Questions

The ASTM D823-18 standard covers specific practices for creating uniform paint and coating films on test panels through multiple application methods. These practices address equipment requirements, process variables, safety protocols, and quality control measures.

What is the scope of ASTM D823-18 and what does it cover regarding film application?

Five distinct practices make up ASTM D823-18, each focused on producing uniform coating thickness on test panels. These practices include automated spray application, motor-driven dip coating, and other specialized methods.

The standard applies to paints, varnishes, and related coating materials used in testing and quality control applications.

Can you explain the methodologies outlined in ASTM D823-18 for achieving uniform thickness?

The standard specifies automated spray machines as one primary method for achieving consistent film thickness.

You must maintain precise control over application speed, distance, and material flow rate during the coating process.

Dip coating requires controlled immersion and withdrawal rates to ensure even coverage.

How does ASTM D823-18 differ from ASTM D3258 in terms of film application?

ASTM D823-18 focuses specifically on creating uniform thickness films for testing purposes. It emphasizes automated and mechanical application methods.

D3258 deals more broadly with paint film evaluation and includes different testing parameters.

What are the equipment requirements specified in ASTM D823-18 for preparing test panels?

You need calibrated automated spray equipment or dip coating machinery that can maintain consistent speeds and distances.

The test panels must meet specific cleanliness and surface preparation standards.

Your equipment must be able to control application parameters like pressure and flow rate precisely.

What variables should be controlled during the application process as per ASTM D823-18?

Temperature and humidity in your testing area need strict monitoring and control.

Material viscosity and application speed require consistent measurement and adjustment.

Distance between spray equipment and test panels must remain uniform throughout the process.

What are the safety considerations to keep in mind when following ASTM D823-18 practices?

You must use proper ventilation when working with paint and coating materials.

Personal protective equipment including respiratory protection, gloves, and eye protection is essential.

Keep all equipment properly grounded to prevent static electricity buildup.